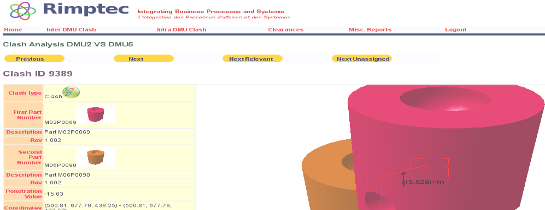

Rimptec EMS

Rimptec Engineering Management System(EMS) helps in Business Process

Re-engineering and/or improving the efficiency of existing business

process by identifying bottleneck thus providing an opportunity for

corrective actions. The EMS is made up of following modules. All the

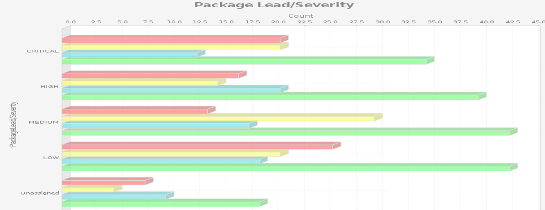

modules have their own reporting mechanisms for data visualization

and performance measurement metrics.

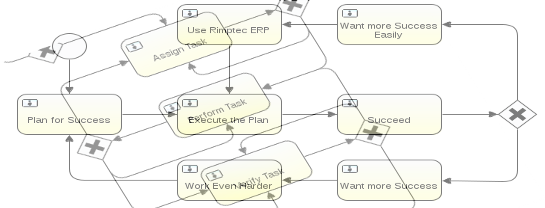

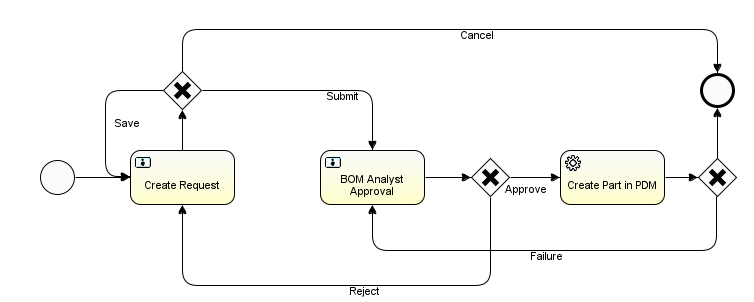

All the workflows

in EMS are BPMN2 standard compliant and are modeled to run on any

BPMN2 compliant work-flow engine. While EMS is primarily developed in the English language

but it can be configured to run in multiple languages.

Current plan is to support EMS

in English, German, French, Spanish, Chinese, Punjabi and Hindi languages.

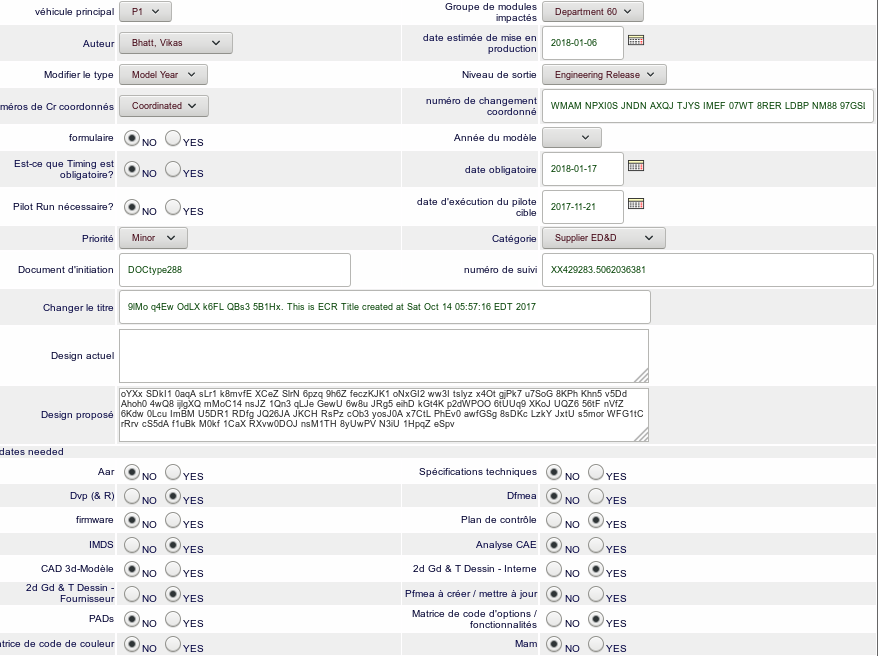

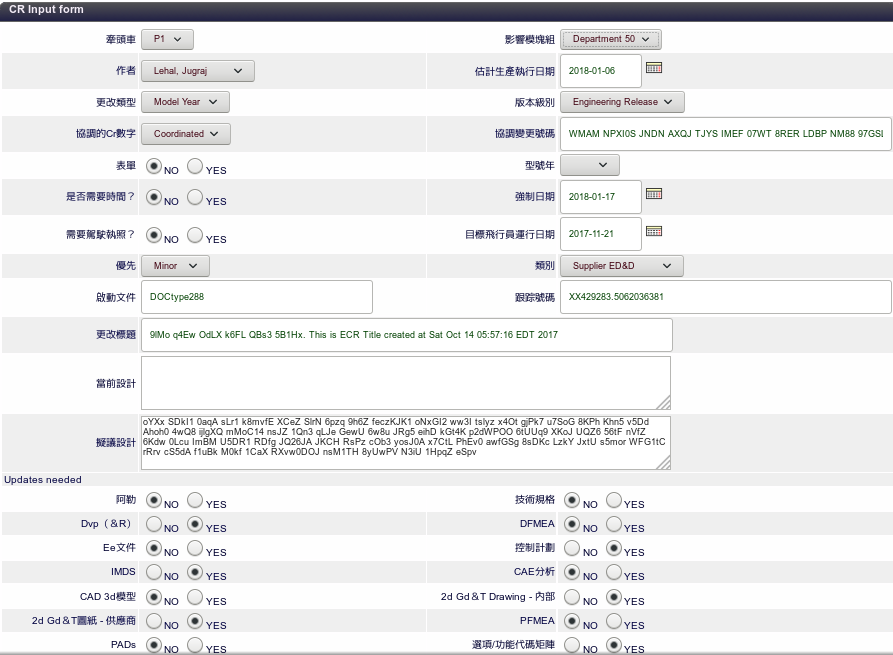

French ECR screen

Chinese ECR screen

Work Requisition & Tracking System

Work requisition and tracking system allows online

requesting,scheduling, updating and monitoring of all the work in

companies or departments involved in any kind of engineering

operations.

Engineering Change Management System

Engineering Change Management System allows online engineering document change control of all engineering/technical documents in any engineering company.

Issue Resolution & Report System

Engineering issue Resolution system helps in recording, tracking and evolving resolution of all the engineering, technical or other issues in any kind of work environment. Workflow conforms to 7-steps approach to issue resolution.

IRRS screen

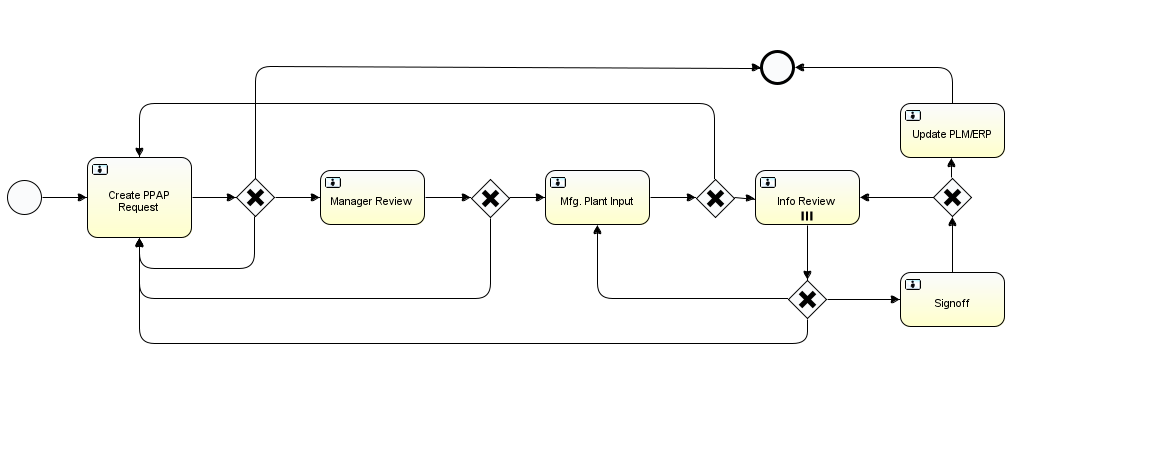

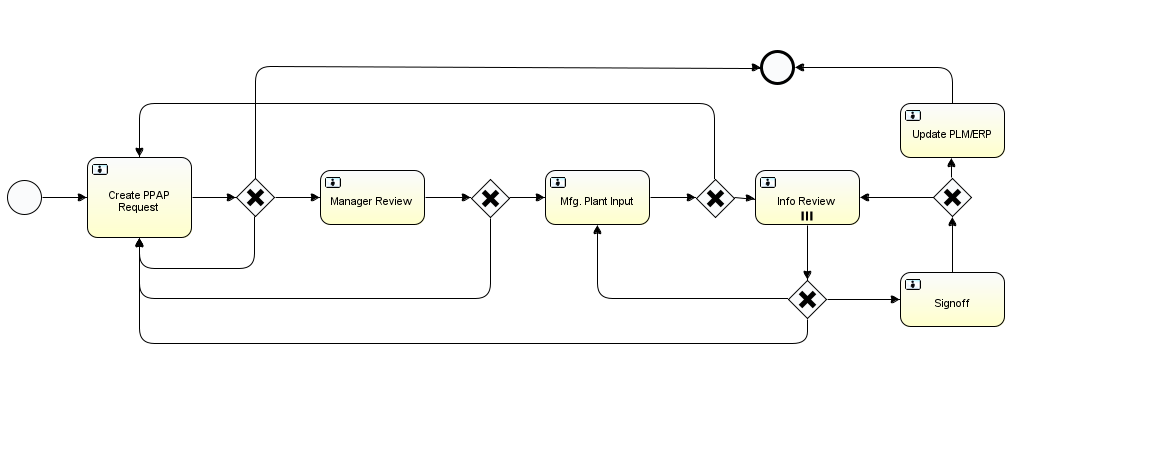

PPAP Workflow

Used by Supplier Quality Engineering for handling all aspects of PPAP for new or revised parts.

PPAP workflow screen

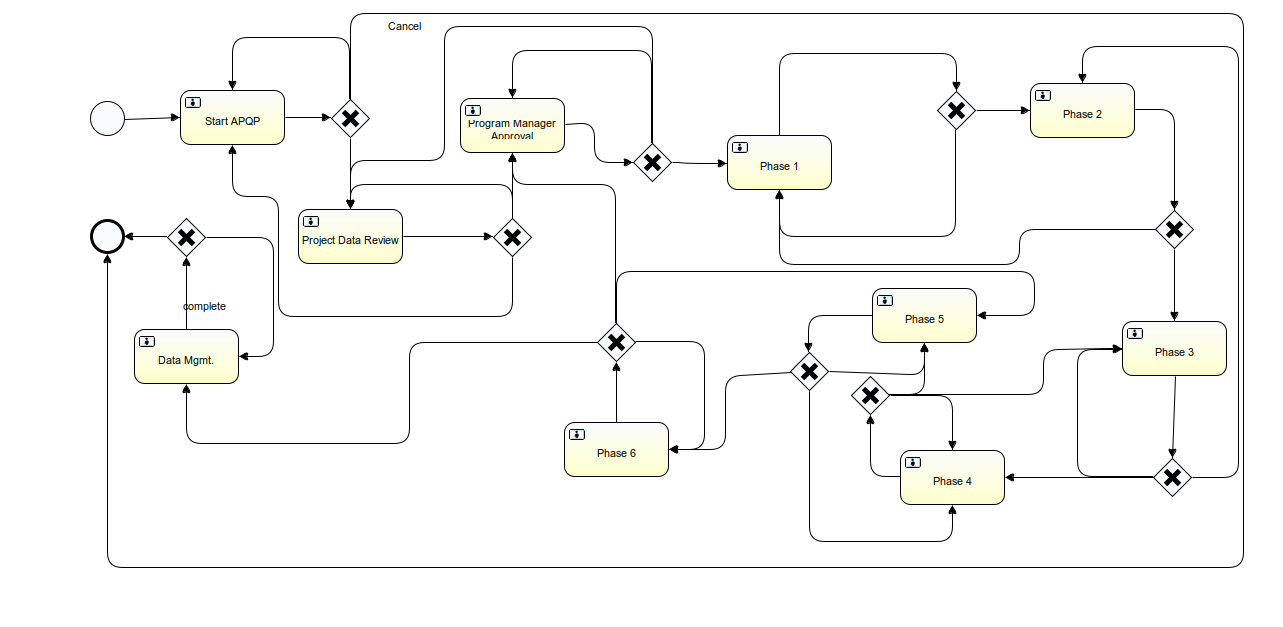

APQP Workflow

Used by Quality Engineering for handling all aspects of Product design thru launch for new or revised parts.

APQP Workflow

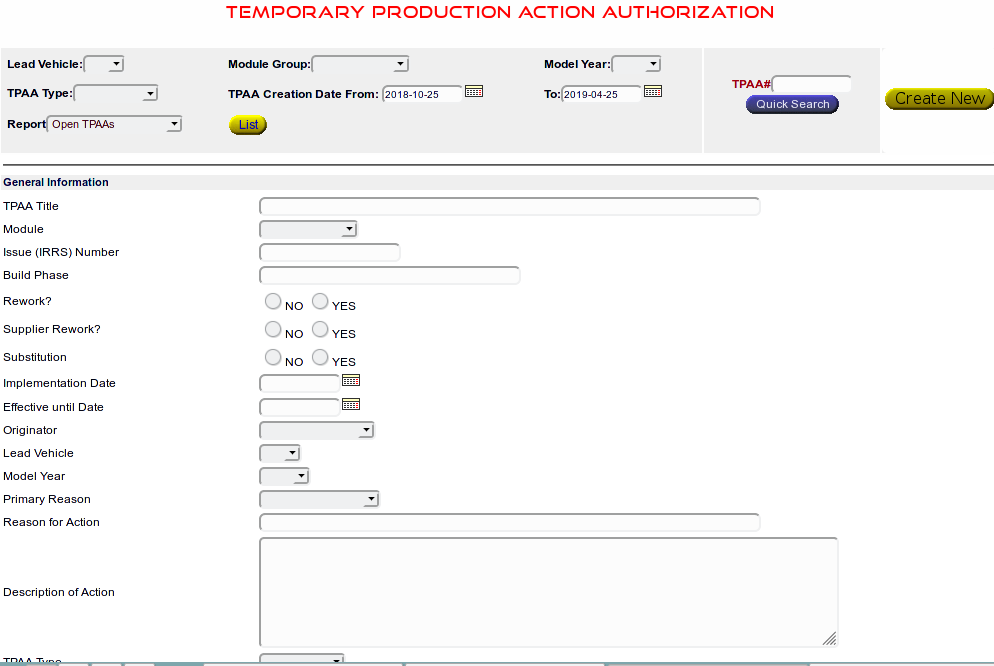

TPAA workflow

Temporary Production Action Authorization (also known as Special Request for Engineering Authorization(SREA)) [similar but not same as Supplier Request for Engineering Approval (SREA),although, the workflow can be used for that too..], Workflow implementing requirements from Manufacturing and Engineering to continue production with deviations from design/manufacturing intent when issue resolution is not immediately possible but established procedures must still be followed.

TPAA screen

Project Numbering Database

Database to efficiently account for resources allocated to various engineering projects.

Part Number Request WorkFlow

Workflow to request new engineering parts numbers based on product type and program, its online approval process and creation of part numbers in the integrated PLM/PDM software.

Document Number Request WorkFlow

Workflow to request new engineering Documents numbers, its online approval process and initial creation of Documents in the integrated PLM/PDM software.

Requestfor Manufacturing Quotes WorkFlow

Workflow to request quotes from suppliers for manufacturing of engineering parts/prototypes/systems etc. for comparative/competitive biding and its online approval process.

Technical Library

Module for making an online library of Engineering Drawings.

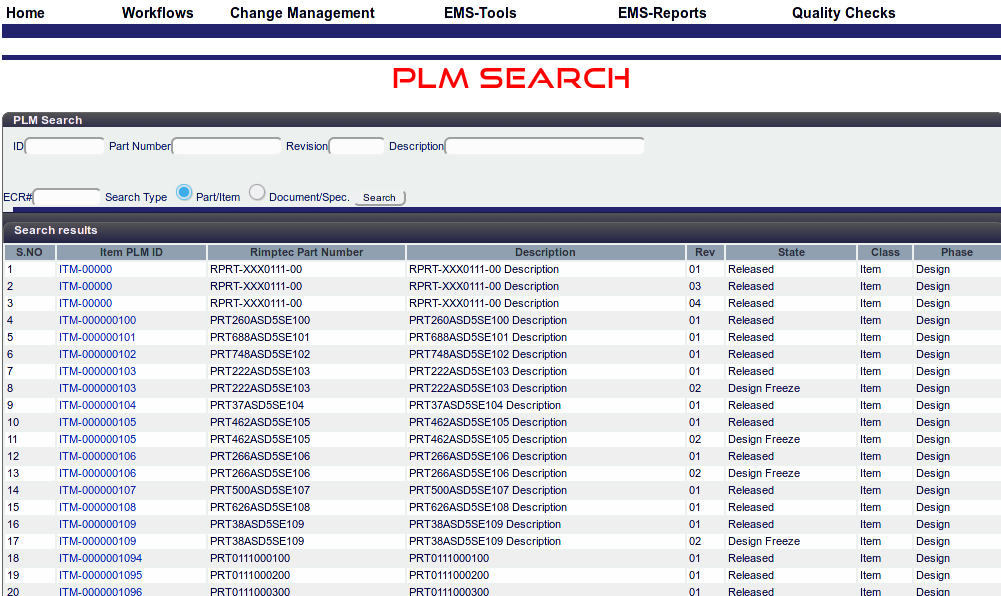

PDM

Product Data Manager, for creating, checking-out and checking in CAD data and other specifications. Design freeze/thaw is also supported. Engineers can create ebom directly as part of Engineering Change Management Process

EMs can be integrated with other COTS PDL/PLM systems such as Teamcenter, Smarteam, Enovia V6 or ARAS etc.

PLM search screen

User Authentication Module

Based on LDAP, can be integrated with Active Directory.

Data Transfer Request Tracker

System for Controlling and recording data transfer to outside suppliers and customers.(discontinued)

Engineering Time Tracker(discontinued)

Expense Report Database(discontinued)

For further information about these modules, please Contact us.